Category

- Uncategorized

- ; Games

- ; Home Improvement

- ; Outdoors

- ; Personal Care

- & Accessories

- & Garden

- & Gourmet Food

- & Home Improvement

- & Outdoors

- & Personal Care

- ames

- amp; Accessories

- amp; Games

- amp; Gourmet Food

- amp; Home Improvement

- Automotive

- Baby

- Beauty & Personal Care

- Clothing

- Clothing & Accessories

- cs

- de Products

- DIY & Tools

- ducts

- e

- e Products

- Electronics

- es

- Games

- Grocery & Gourmet Food

- Handmade Products

- Health & Household

- Health & Personal Care

- Home

- Home & Kitchen

- Home Improvement

- ies

- Industrial & Scientific

- ive

- Jewelry

- Kitchen & Dining

- Lawn & Garden

- mp; Accessories

- mp; Games

- mp; Gourmet Food

- mp; Outdoors

- mp; Personal Care

- Musical Instruments

- n & Garden

- nics

- oducts

- Office Products

- onics

- p; Home Improvement

- p; Outdoors

- p; Personal Care

- Patio

- Pet Supplies

- plies

- pplies

- Products

- roducts

- s

- s & Outdoors

- Shoes & Accessories

- Sports & Outdoors

- Stage & Studio

- tive

- Tools & Home Improvement

- Toys & Games

- upplies

- Video Games

- Watches

- wn & Garden

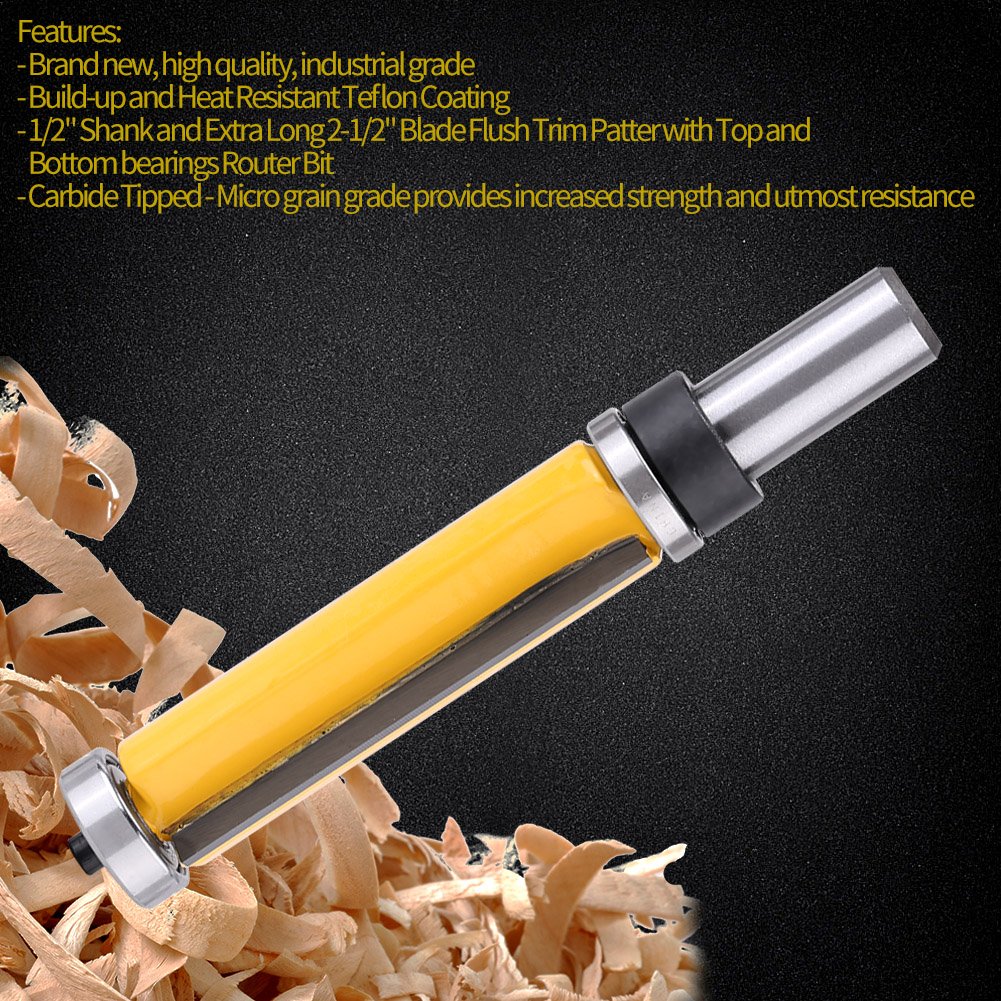

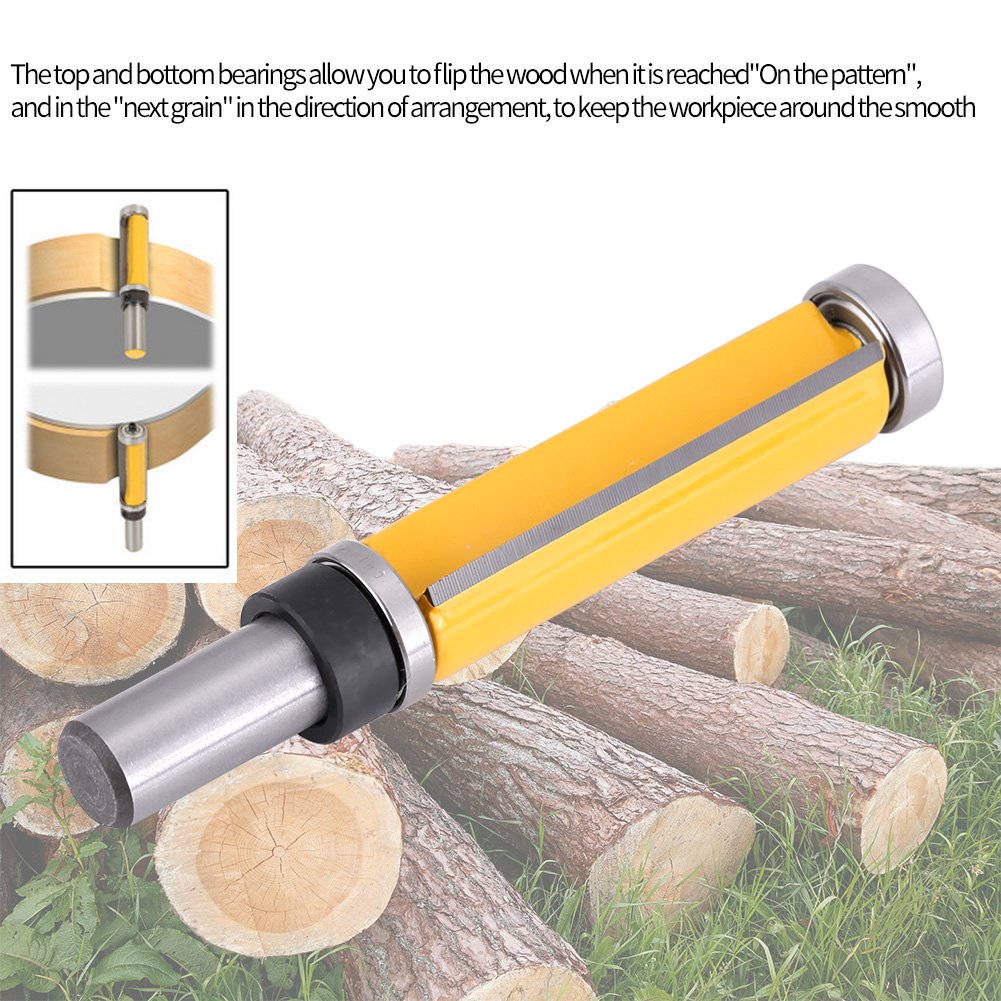

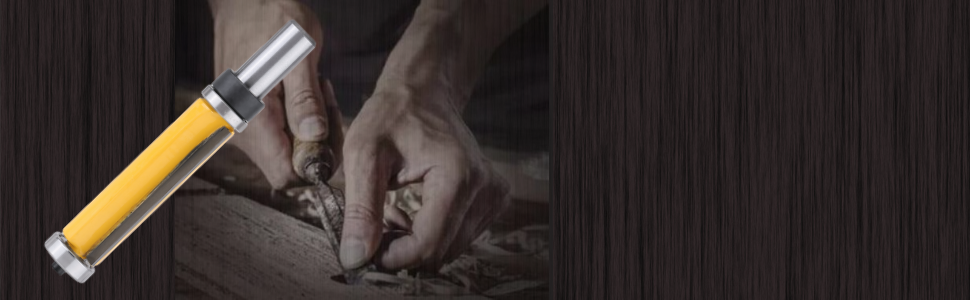

1/2″ Shank Straight Router Bit Woodworking Flush Trim Router Bit Tool 2-1/2″L x 3/4”Dia with Long Cutter, Top and Bottom Bearing

$34.06 Original price was: $34.06.$28.38Current price is: $28.38.

- Professional grade cemented carbide, high hardness and durable, long service life

- Industrial quality router bits with sharp cutting edge can improve working efficiency

- Heat resistant coating design prevents build-up of sawdust and resin

- Great for finishing a wide range of materials including solid wood, MDF, chipboard, plywood, etc

- Well packaged in bubble bag, safety and quality guaranteed

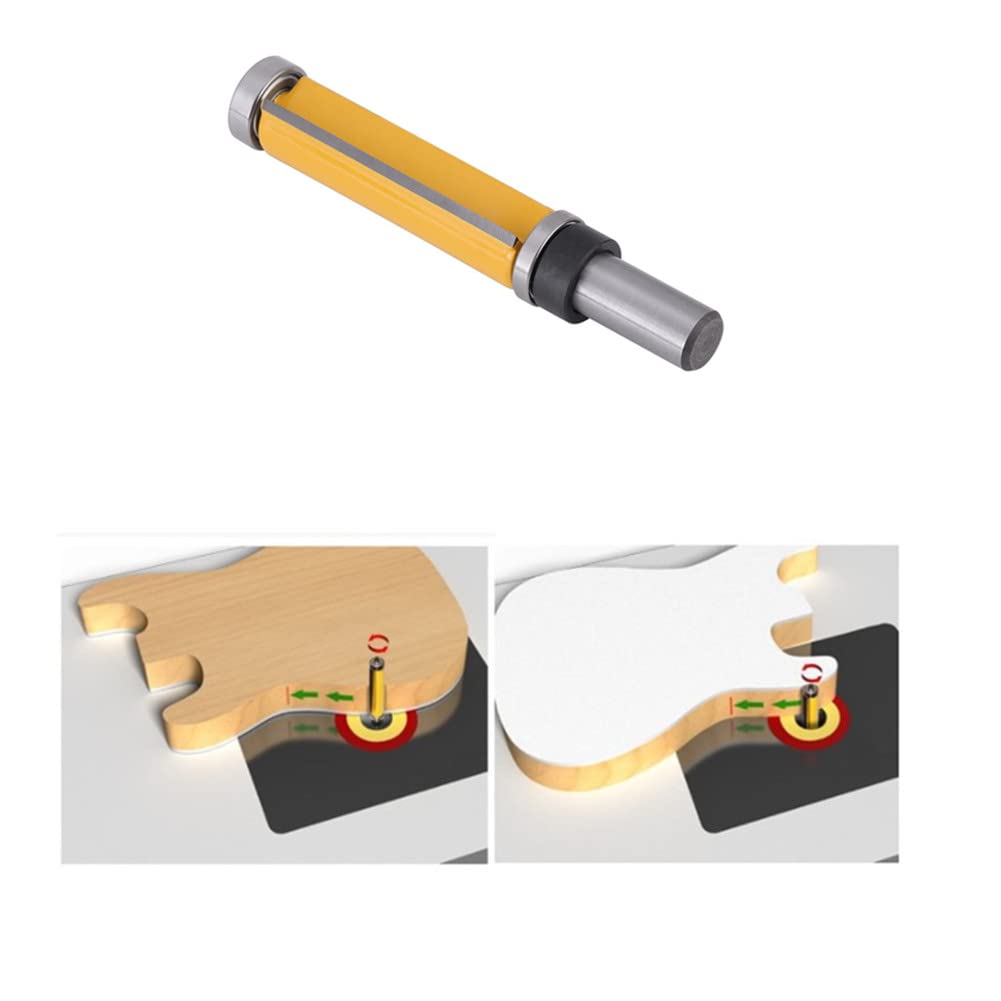

WOODWORKING BEARING FLUSH TRIM ROUTER BIT TOOL

THIS WOODWORKING BEARING FLUSH TRIM ROUTER BIT TOOL IS USUALLY USED ON ELECTRIC WOOD CUTTERS OR ENGRAVING MACHINES TO TRIM WOODEN EDGES. IT CAN BE USED TO TRIM VARIOUS MATERIALS, INCLUDING SOLID WOOD, MEDIUM DENSITY FIBERBOARD, PARTICLE BOARD, PLYWOOD, ETC.

DETAIL

|

|

|

|

|---|---|---|

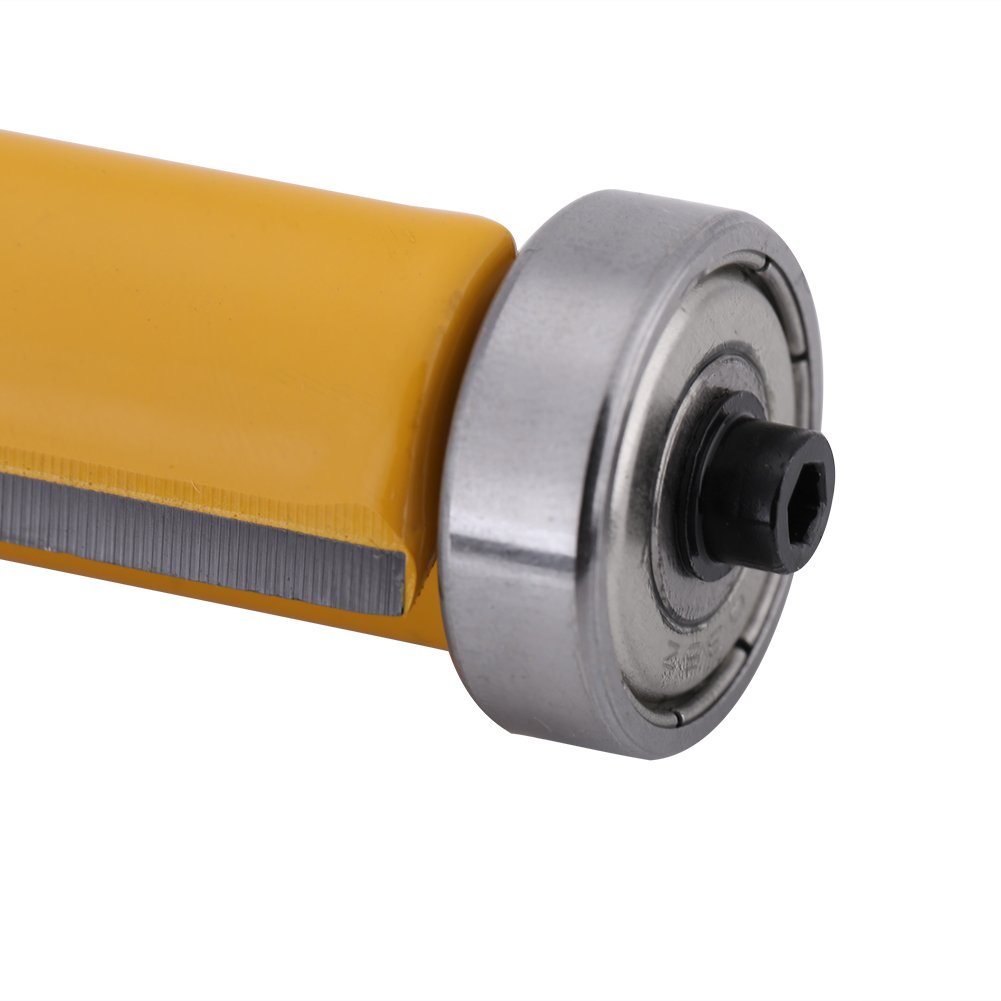

LOCATING BEARINGHIGH-QUALITY POSITIONING BEARINGS IMPROVE WORK EFFICIENCY AND ENSURE STABLE CUTTING |

HEAT-RESISTANT COATINGTHE YELLOW HEAT-RESISTANT COATING PREVENTS WOOD CHIPS AND RESIN FROM ACCUMULATING. |

CARBIDE TOOL HOLDERCARBIDE DRILL BIT, MAINTAIN HIGH HARDNESS AND DURABILITY, CAN BE USED FOR A LONG TIME |

- Tool selection

To achieve what you need, be sure to use short-edged knives as much as possible. Too long cutting edge or too long tool body will cause vibration and deviation during machining, which will damage the tool and affect the quality of machining. It is recommended to use a tool with a larger shank diameter.

- Tool operation

- Woodworking milling cutters are specially designed for portable and desktop woodworking engraving machines, and cannot be used on electric drills, drill presses and other equipment.

- The tool can process hardwood, softwood, synthetic board and other wood to polish a smooth surface, but avoid processing metal materials such as copper and iron and non-wood materials such as sand and stone.

- Be sure to use the appropriate size of the jacket, because the wear is serious, the jacket is not round enough or the hole with the taper can not provide enough clamping force, which will cause vibration or twist the tool handle and fly off.

- When the tool handle is found to have uneven contact marks or dents after the tool is clamped, it indicates that there is slippage and the inner hole of the jacket is changed. At this time, the jacket should be replaced immediately to avoid accidents.

- After the tool is clamped, if the tool is found to be bounced while working, it should be stopped immediately, and the clamping should be repeated several times to allow the tool shank and the jacket to get sufficient contact before working.

- The contact between the tool shank and the jacket should be good. The tool shank must be completely inserted into the jacket and tightened firmly, so as to provide sufficient clamping force for the tool. Only a small part of it cannot be inserted into the jacket, otherwise it will be easy. The tool handle is broken and the tool is damaged.

- Use proper eye and ear protection devices during operation, and keep your body, clothes and other sundries away from the working tool

Related products

-

410 Stainless Steel #8 Self Drilling TEK Screw Assortment Kit, Hex Washer Head & Modified Truss Head, VIGRUE 370PCS Self Tapping Sheet Metal Screws, Length 1/2″ to 1-1/4″, Black Oxide

$47.51Original price was: $47.51.$39.59Current price is: $39.59.Add to cart- ?Screw Type: #8 Self Tapping Drilling Metal Screws Assortment Kit.(#8 for 3mm carbon steel sheet to avoid breaking off. Min Breaking Torque-2.8N.M)

- ?Sizes: #8 x 1/2”, #8 x 5/8”, #8 x 3/4”, #8 x 1”, #8 x 1-1/4” Self Drilling Screws(Each Head).

- ?Head Type: Hex Washer/Modified Truss Head; Drive Type: External Hex/Phillips; Point Type: #2.

- ?Made of 100% 410 Stainless Steel and with Black Oxide coating, giving the screws an excellent corrosion and abrasion resistance.

- ?Self Drilling Screws (sometimes called self-tapping screws) are perfect for use in sheet metal steel, aluminum, wood, plastics, and other similar materials, self-drilling makes pre-drilling unnecessary.

-

VASLON 100-piece Sandpaper Set ?C 5 Inch 8 Holes Sanding Discs 10 Different Grades Including 60, 80, 100, 120, 150, 180, 240, 320, 400, 600 Grits for Random Orbital Sander

$30.08Original price was: $30.08.$25.07Current price is: $25.07.Add to cart- 100-PIECE MULTI-GRIT SANDPAPAER SET: Including 60, 80, 100, 120, 150, 180, 240, 320, 400, 600 grits, helps you make the proper and efficient polishing work from rough to fine grits. The higher the number, the finer the grit

- GREAT POLISHING EFFECT: Sanding pads are made from high quality aluminum oxide abrasive, durable and anti-static, provide great cutting force and a smooth finish on your project

- 8-HOLE DUST EXTRACTION DESIGN: 8 holes for efficient dust extraction. And back of napping make grit removal and replacement quick and lengthen the life of each disc

- UNIVERSAL COMPATIBILITY??5 inch(125mm) sanding discs fit universal orbital sander, such as BLACK+DECKER, DEWALT, Bosch, Makita, PORTER-CABLE, etc

- WIDE APPLICATIONS: Ideal for grinding and finishing on metal and non-metal, wood, rubber, leather, plastic, stone, glass and other materials

-

LED Work Light, eecoo COB Rechargeable Inspection Lamp with Magnetic Base 360??Rotate and 5 Lighting Modes Ultra Bright LED Flashlight, Portable Torch Light for Car Repair, Emergency, Workshop 1 PCS

$38.00Original price was: $38.00.$31.67Current price is: $31.67.Add to cart- ?5 Working Modes??: High Brightness / Medium Brightness / Front Lighting / Red Warning / Strobe Red. The front lighting can be inserted into a small corner or narrow slit to fix problem or find something. Red warning light help ensure your safety in emergency, turn on the red warning lighting by press the button of the rechargeable work light for 3 seconds

- ?Magnetic Base & Swivel Hook??: Magnet c-clip is great, it can stick battery work light firmly to car or any metal surface, free your hands for doing the work occupying two hands. Swivel hook hidden at the bottom of the led flashlight, easy use for emergency roadside repairs, work at night, or multipurpose work

- ?360??Rotation & IP68 Waterproof??: The COB LED work light can rotate horizontally 360??, focus the inspection lamp on the exact working area as your needs. It is very suitable for auto repair, home lighting, power outages, Camping and Emergency. IP68 waterproof design, but do not put portable work light into water

- ?Lightweight and Durable??: The work light is made of lightweight, durable ABS thermoplastic material, which is waterproof and impact resistant. The COB lamp can emit a larger light area and less gloss than traditional LEDs, and a larger cooling surface generates less heat to extend its life (over 100,000 hours)

- ?COB + LED 2 In 1 Work Light??: 3W COB work light provides a strong white flood light for large areas such as workshop; LED flashlight can be used as a standard flashlight, it also provides slight bright focus for remote lighting. And it equipped with built-in rechargeable battery and USB cable included

-

Preciva Grommet Tool Kit, Portable Handheld Hole Punch Pliers Grommet Kit, Hand Press Machine Manual Puncher with 500pcs Silver Grommets of 3/8 Inch

$117.36Original price was: $117.36.$97.80Current price is: $97.80.Add to cart- ??500Pcs Grommet Eyelets and Washers?? Equip with 3/8 inch (10mm) gromments, that are neat, beautiful and firm. Strong penetrating power makes them can be easily buttoned up. They are made of stainless iron, chrome-plated on the surfaces, for long life span. Not easy to rust.

- ??Supr Performance?? Manual eyelet puncher is designed with the lever principle. Using the mechanics principle fully, Preciva grommets press can make people save more than 50% strength. The handle made of anti-slip engineering rubber material is anti-friction and anti-slip. The unique design of the index finger protruding part makes it easier to use.

- ??Double Magnetic Mold?? The jaws of this grommet pliers are magnetized to fix the eyelet and washer quickly and well, so you can improve the working efficiency. The handle with opening angle, you can press it by only one hand.

- ??Widely Application?? Don’t need to sew or crop before using punching machine grommet kits, you can easily punch holes just with this tool alone (Grommet Tool Kit Included Manual), which can be applied in PVC banners, tarpaulin, cardboard, printing canvas etc.

- ??Leading Service?? Depend on our reputation and customer satisfaction, we have succeeded and will try our best to make every customers satisfy with the item. Hope you can enjoy a pleasant shopping experience! If you have any questions or opinions, please feel free to contact us.